One of our Clients approached us with a project to design and build an alternative transfer hatch design for their manufacturing facility in Manchester requiring replacement of 35 trolley hatches that were constantly failing causing manufacturing delays.

We also had an idea of a rotating door – why not open the door into the upper unused head space instead of opening out into the cleanroom space?

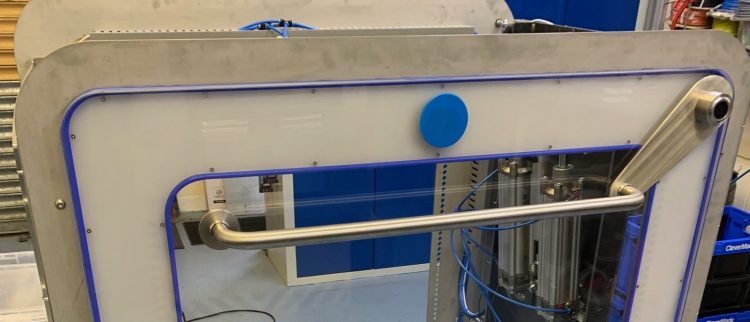

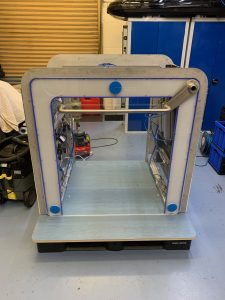

So we started on the journey of designing a prototype – we called it the Fulcrum hatch.

Very early on we realised the cost of this hatch was going to far exceed our Clients budget so for them we focused on another design which was installed and commissioned in 2018 and currently no issues / breakdowns to date.

However, we had started the Fulcrum hatch project and decided to see it through…

We also thought – why not make if fully automated? So we did.

We built a fully operational, fully automatic Fulcrum hatch and WOW was it fun to watch it operating.

It took many prototypes and cost us a fortune but we loved the process of achieving our end goal.

Fully Automatic, touch free activation with voice announcements and count down lighting.

We just need to find a Client wanting to spend £25k on a transfer hatch…

In the end, It was just a bit of fun and we learnt a lot.